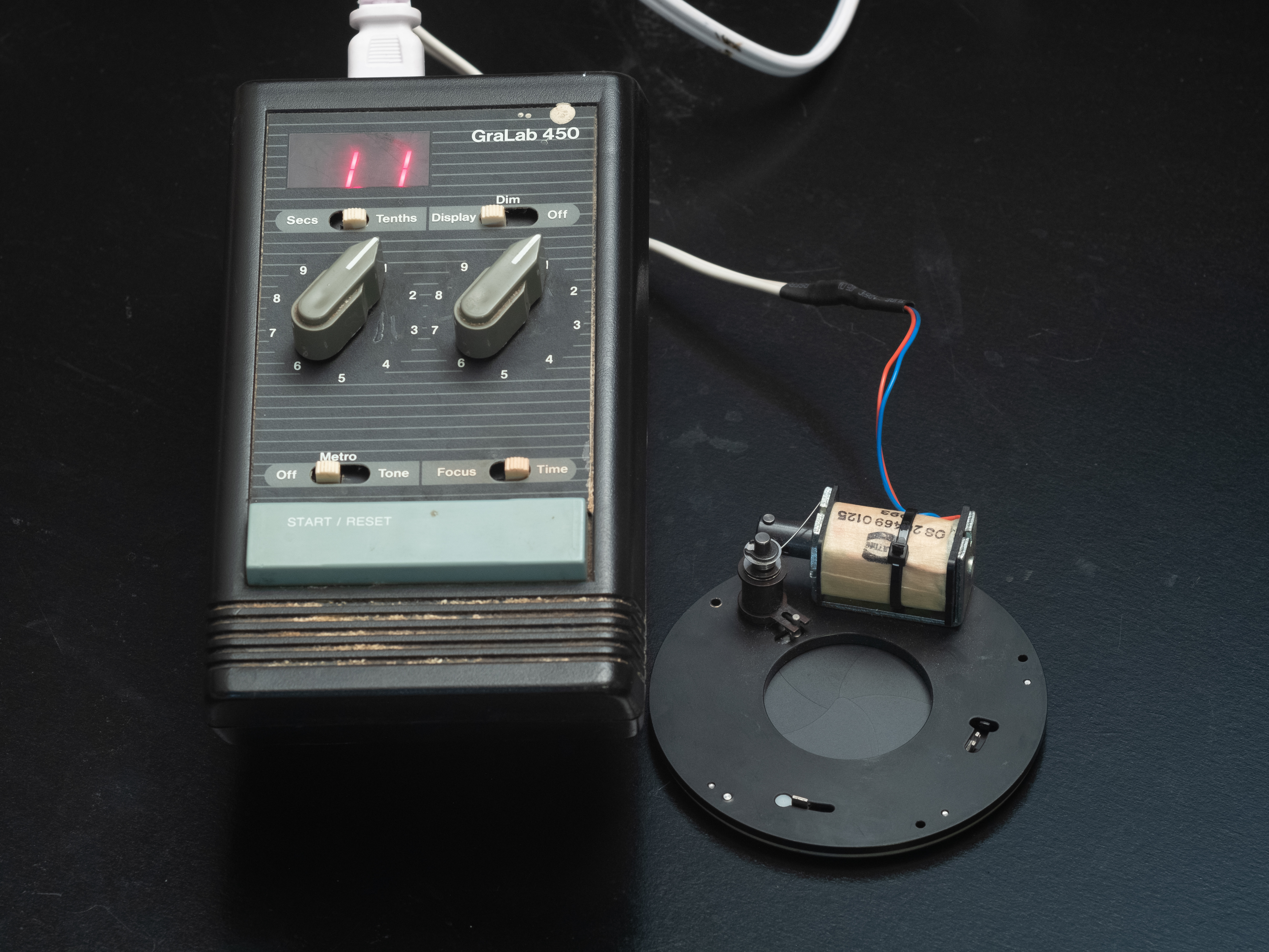

BW DM70 with custom electrostatic panel

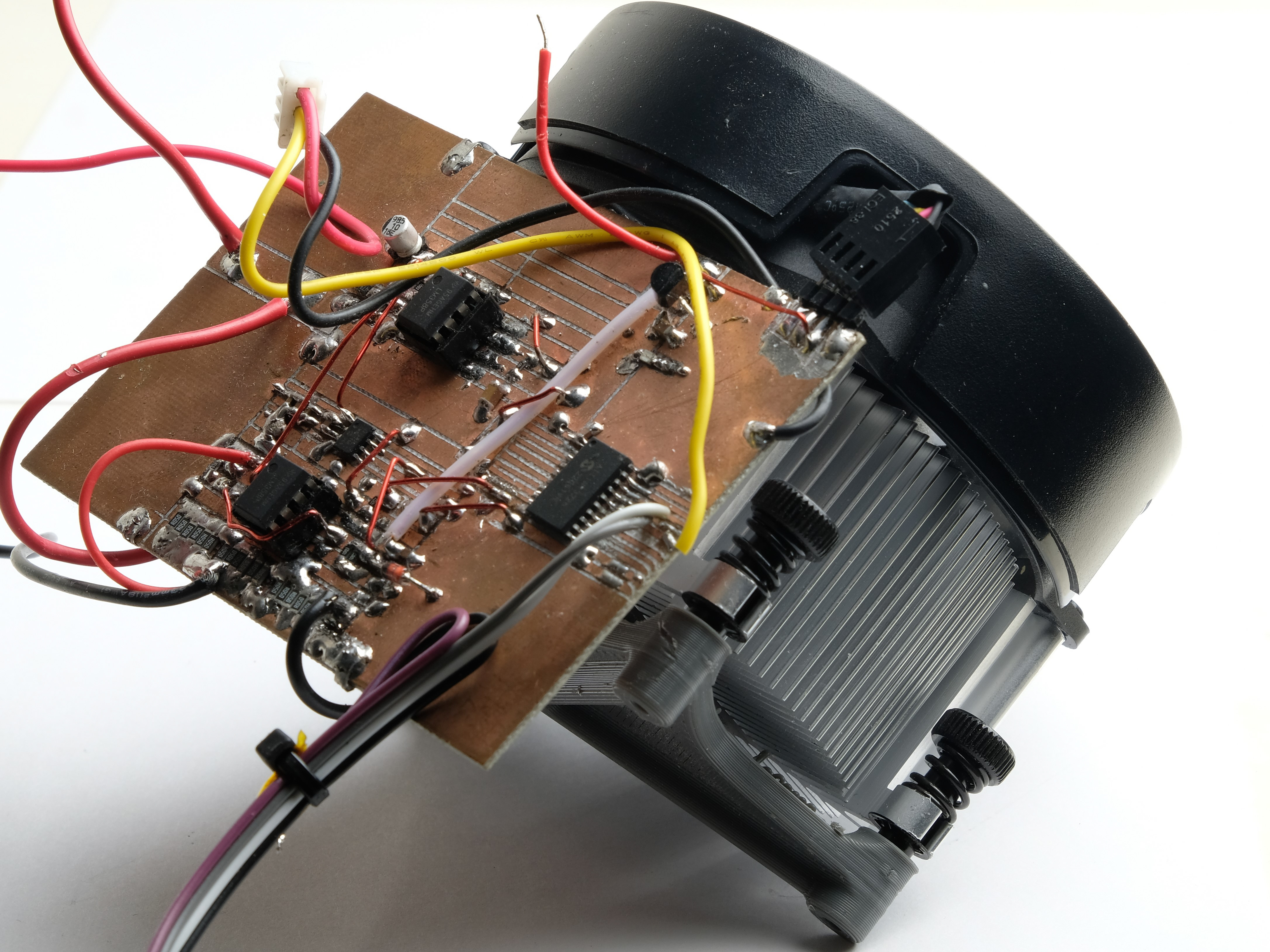

Speakers produce sound by vibrating a diaphragm, which modulates air pressure. Conventional speakers use a stiff cone as the diaphragm, to which is attached a coil in a magnetic field. Audio current through the wire produces a Lorentz force on the coil, which moves the diapgrahm. The stiffness of the cone provides the restoring force. This approach, based on magnetic force, has the advantage of producing high forces suitable for large movements at low frequency; bass notes. But since the diaphragm and coil are relatively massive, the response is attenuated at higher frequencies. The subwoofer housed in the cabinet of pictured above operates to about 500 Hz.

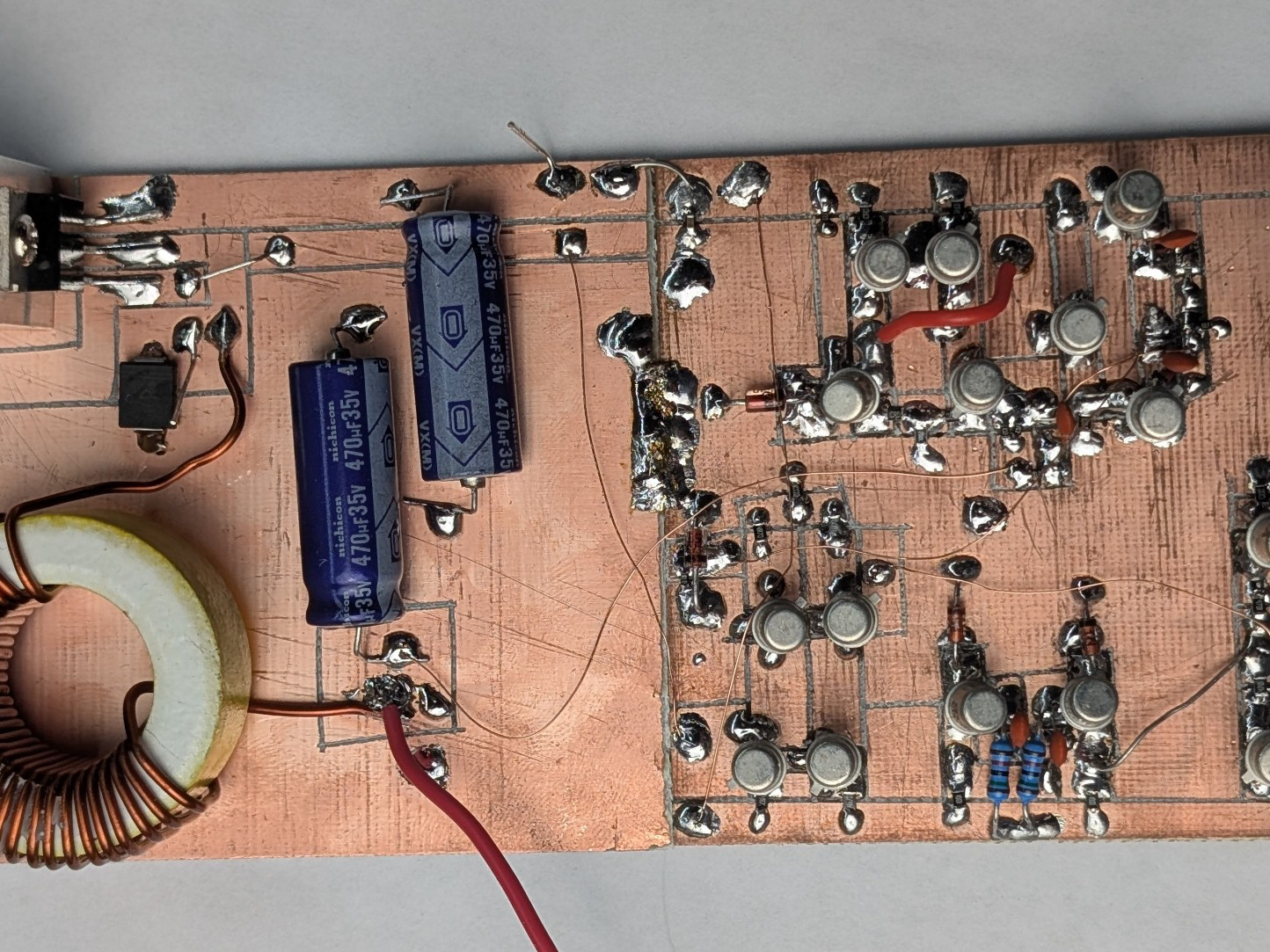

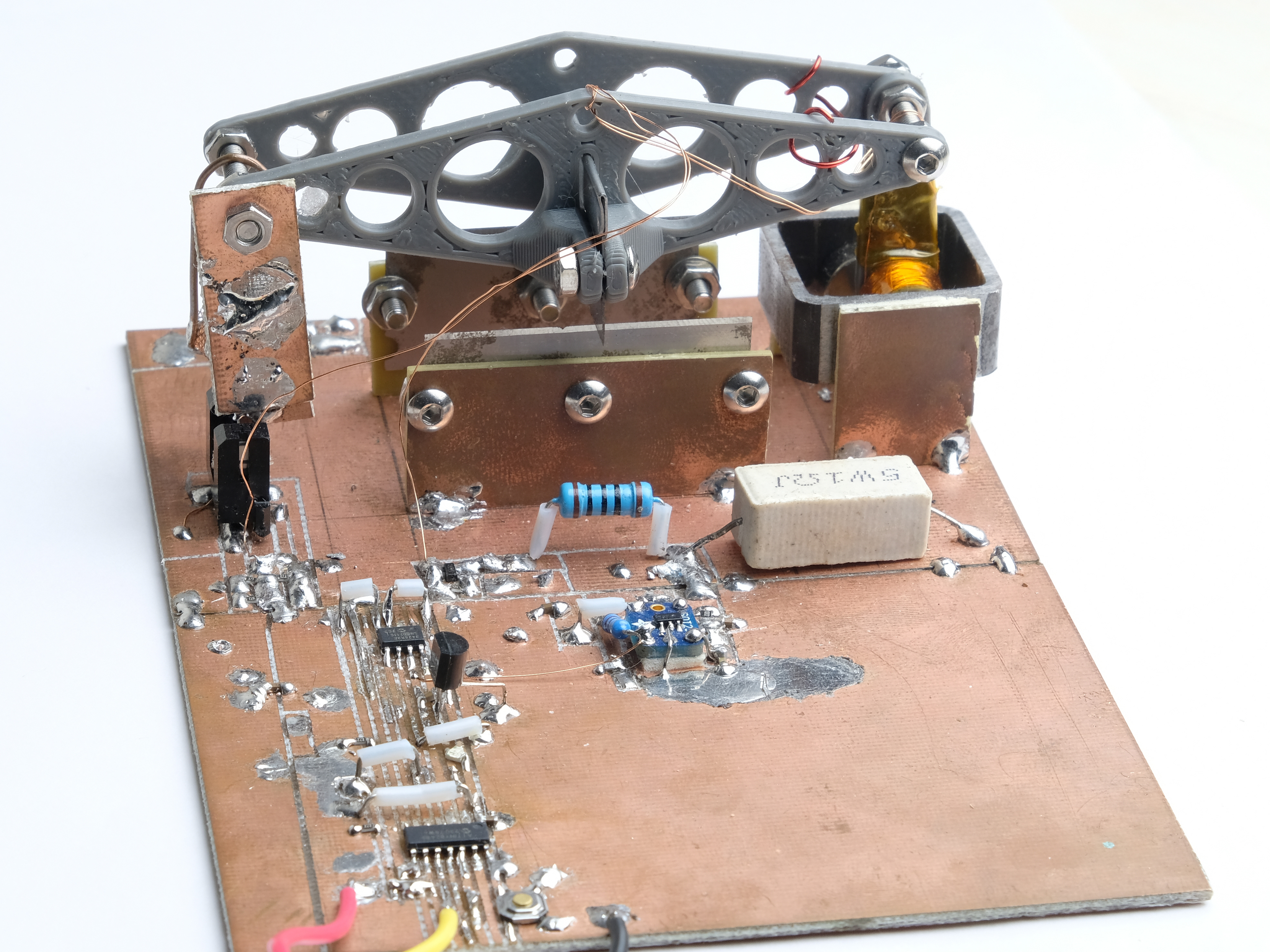

Electrostatic speakers function on electrostatic force. The stiff cone is replaced by a wafer-thin tensioned polyester membrane, which by aid of a marginally conductive coating (Licron Crystal) is charged to several thousand volts. The coating has an extremely high resistivity on the order of teraohm meters. This 'locks' charge to the diaphragm, relative to audio frequencies. Then the audio signal (also at several thousand volts peak-peak) is applied to two stators on either side of the membrane. By means of a center-tapped transformer the swing of the audio signal is placed about the DC bias on the diaphragm. Then the electrostatic force between charge on the stator plates and the static charge on the diaphragm produces a deflecting force, and sound is produced. The advantage of this method is the extremely low mass of the diaphragm - in this case 6um polyester, which has a mass area density equivalent to a 1/4" thick layer of air. As a result, electrostatic speakers excel at reproducing high frequency notes.

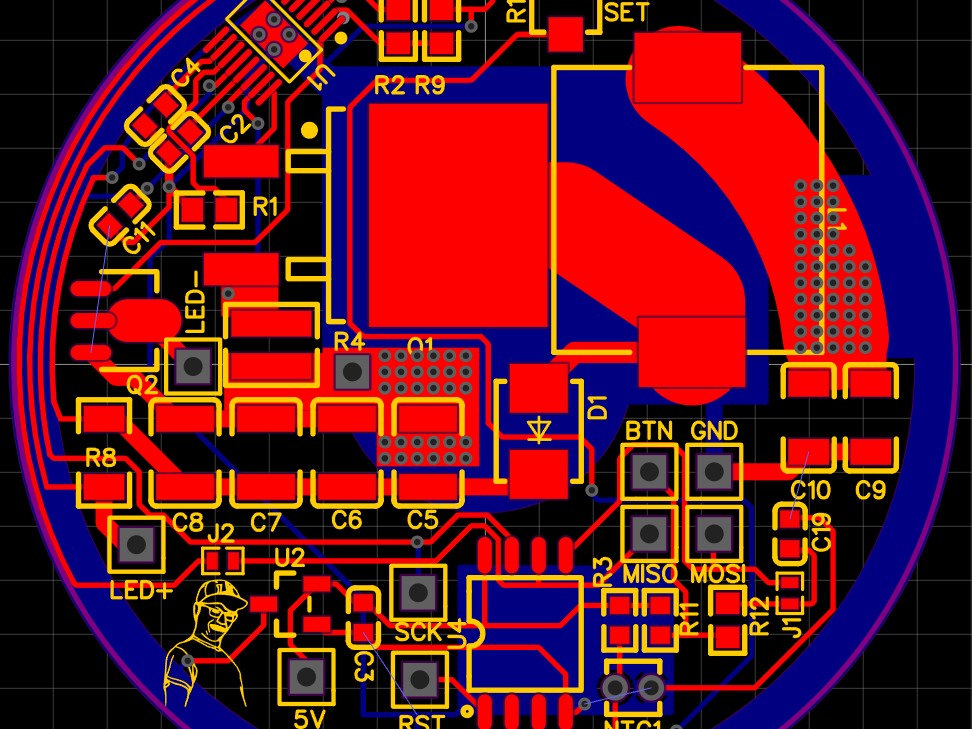

RED: Copper, inwards facing, solder masked. BLUE: Copper, outwards facing, mostly unmasked

The speaker is constructed from a pair of identical printed circuit boards, each 5.125 x 25" (13 x 63 cm). In the board above the copper in red forms the stators. When charged by the high voltage audio signal, which enters by one of the reverse-side copper contacts in blue at the center bottom of the PCB, these hold the charge which develops force against the charge in the diaphragm. The board is symmetrical, so it can be used for both sides of the speaker. Each board in a pair takes one stator wire, which connects by a circular lug at the center contacts. Also, just one board in a pair takes a DC connection to one of the outer blue contacts. This reachs the diaphragm by copper tape which is applied copper-side out on the foam tape, so it presses against the diaphragm when the panels are pressed together. The copper tape is then passed around the edge of the panel and soldered to the oval pads in the corners (not shown in the diagram below).